plastic extrusion melt pump main structure

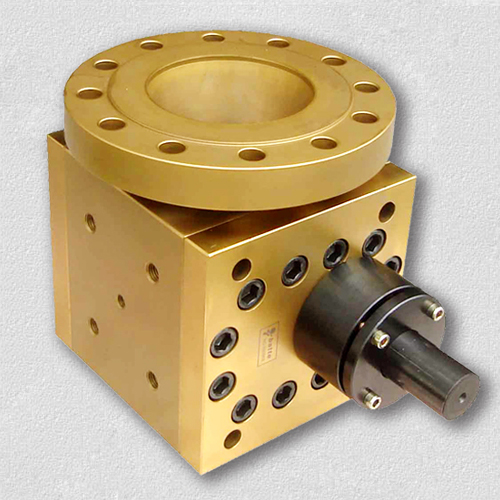

A complete gear pump includes a motor, a gearbox, a coupling, and a few parts of the pump head,

Is composed of pump shell, front and rear side cover, gear shaft, sliding bearing and shaft seal.

1. 1 plastic extrusion melt pump shell

The pump housing is a pair of cylindrical shafts and bearings that are fitted in a housing with a rectangular cross-section.

Pump shell is generally the overall casting, the shell is covered with insulation jacket. Both sides are inlet and outlet flanges, inlet diameters

Larger than the export, which for high viscosity, the end of the pressure suction conditions is particularly important, can improve the pump efficiency and operation

Stability. Front and rear side cover is actually a flat end cover with a jacket. The inside of the surrounding high temperature sealant,

Through the high-strength bolts and pump body closely together to prevent the melt leakage.

1. 2 gear shaft high temperature gear pump has a pair of gear shaft, a long axis, a short axis, long axis is the drive shaft,

The short axis is the driven shaft, the gear sleeve and the shaft are integral, but also for the small pump also welded or by the key

With the connection. Gears are spur gears, helical gears, herringbone gears tooth profile with involute profile and circular teeth

Profile commonly used is involute spur gear, high temperature gear pump gear often used variable gear, the general teeth. The number of 8-18.