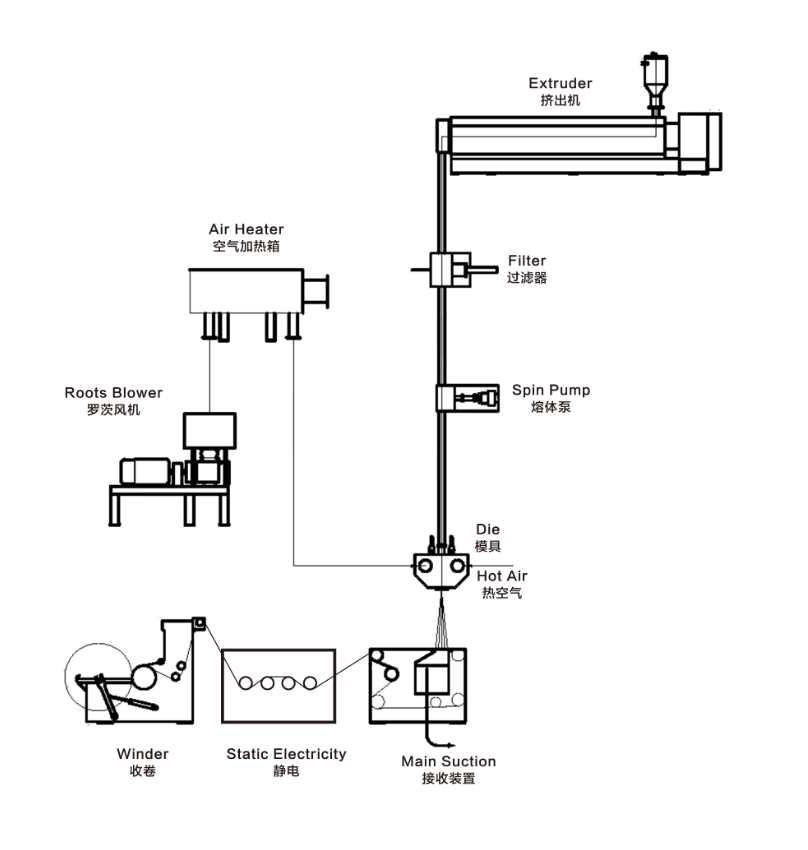

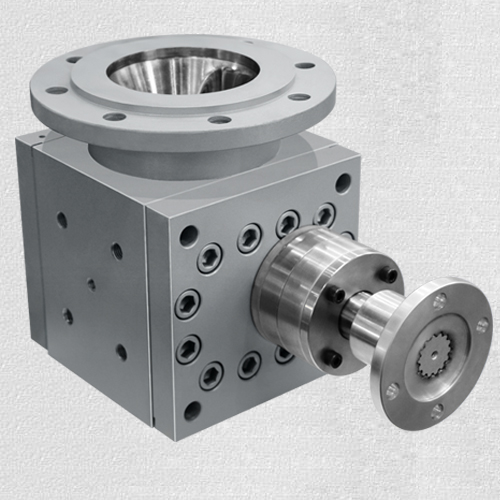

The polymer masterbatch is put into the extruder and melted in the extruder at a temperature of about 240 ℃ (for the main resin used in PP melt blown method). The melt flows through the metering pump to the melt blown die head. The metering pump measures the melt flow output to the nozzle. The spinneret is a capillary tube with a spacing of less than 1mm and a diameter of 0.2-0.4mm. On both sides of the capillary is the air inlet, adding 250-300 ℃ compressed air. When the newly formed polymer extrudes the spinneret, the head end of the compressed air acts on the polymer, and the hot filament is drawn to a diameter of 1-10 μ m by an air flow higher than the sound speed (550m / s). According to its physical characteristics, this kind of net is called microfiber net. When the hot air flows down, it mixes with the surrounding air, which makes the fibers cool and finally consolidate into short and fine fibers.

Melt preparation → filtration → metering → melt extrusion from spinneret hole → melt draft and cooling → mesh forming

pre:what is melt blown non-woven fabricproducted by melt pump

next: Daily maintenance strategy of screw extruder for melt gear pump