The high-pressure pipeline booster pump is especially suitable for the reaction transportation and pressurization of high-temperature and high-viscosity polymer melts that require high output pressure, such as resin, chemical fiber and other industries. It is generally installed in the melt pipeline for pressurization. Pump; it can also be installed in the extruder system that needs heat medium heating to be used as a metering pump. The melt booster gear pump transports prepolymers and polymers such as PET, PBT, PS, ABS, etc. in a very gentle manner, and the melt booster pump is heated by heat transfer oil or electric heating. Zhengzhou Bart ZB-D series melt booster pumps are used where the process requires particularly high pressure, such as: granulation, fiber production or spinning, etc. The design of the melt booster gear pump can also be customized according to customer requirements.

Main technical parameters of high pressure pipeline melt booster pump:

Conveying medium viscosity: 0.0001Pa.s~40000Pa·s

Suction pressure: Vacuum (-0.00~-0.05MPa)~16MPa

Output pressure: 0~35MPa

Differential pressure: ≤25MPa

Operating temperature: ≤350℃

Heating method: heat medium jacket / runner heating / electric heating / no heating

Heat medium pressure: ≤1.6MPa

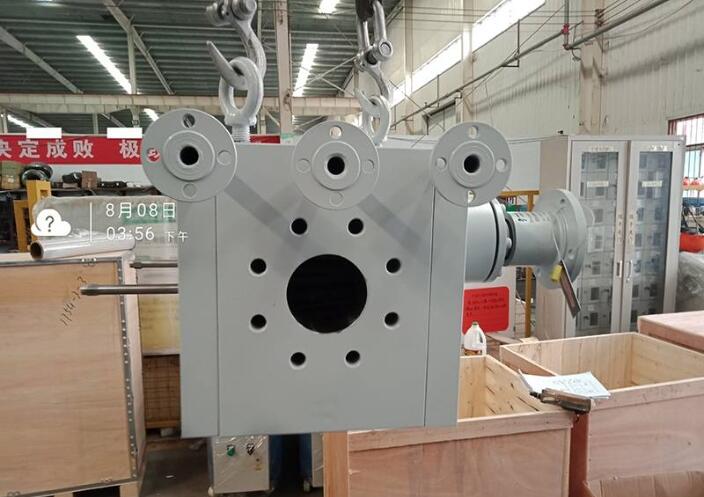

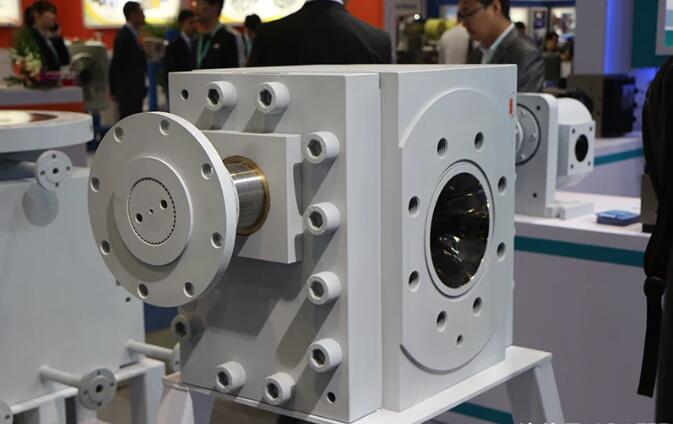

Installation of the melt gear pump:

It is generally installed in the melt pipeline and used as a booster pump or a metering pump. It is driven by a motor + reducer + universal joint, or it can be driven by a gear motor + elastic coupling; gear motor + universal joint drive ; Magnetic drive and other installation methods, our company can provide matching supply according to the different working conditions of customers.

The polymer melt pump is composed of a pump body, a front cover, a rear cover, a driving shaft, a driven shaft, a shaft sleeve and a seal. Body material of melt booster pump: high temperature tool steel, stainless steel, chromium-nickel alloy steel; gear material: tool steel, nitrided steel, optional coating; shaft seal form: thread seal, packing seal; conveying material with high viscosity 40.000.000 mPas; service temperature up to 350 degrees Celsius; suction pressure vacuum up to 120 bar; differential pressure up to 250 bar; melt booster pump specifications from 0.5CC to 20000CC.

pre:Explanation of friction bearing technology of melt metering pump