We are here to help.Easy ways to get the answers you need.

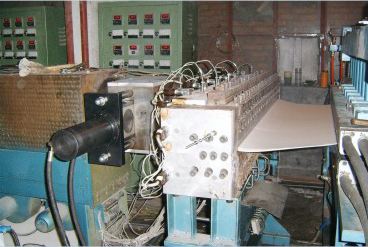

Wire drawing production is divided into two forms: flat wire and round wire. The wire drawing industry can be divided into fishing net wire, lawn wire, strip broom wire, toothbrush wire, wig, rope wire, woven tape, chemical fiber spinning wire and so on from the production of products.Plastic wire drawing machine screen changer is a non-stop screen changing device, consisting of the main body, screen block and pressure receptor, the left part of the main body is equipped with unloading orifice, compared with the existing imported technology to save energy, reduce equipment costs, and easy to ensure product quality, the screen changer is also suitable for film blowing machines, extrusion machines, granulators and other plastic molding machinery.

Polymer melt gear pump has been widely used in chemical fiber, pelletizing, plastic film, sheet, plate, profile, pipe, wire and cable, wire drawing, compound extrusion and other production lines, the materials can be processed almost cover most polymer materials, such as: PE, PC, PP, PVC, HIPS, PS, PA, TPUR, fluoropolymers, polysulfone, polyester, thermoplastic elastomer, rubber and Thermal adhesives, etc.

1, to buy manufacturers with many years of production experience, because the melt pump belongs to the high precision equipment, not only the manufacturing process requirements and relatively complex processing; high requirements for processing accuracy, the pump body and gear clearance, gear shaft and bearing clearance need to be controlled in the silk category (1 silk = 0.01 mm).

2, now on the market engaged in melt pump manufacturers, the melt pump provided, no strict processing technology processing, as well as professional and technical personnel precision assembly, in the actual use of the process will lead to leakage, the phenomenon of frequent pump card. This is why many rubber and plastic production line users to buy Zhengzhou Bart melt pump.

3, the market currently provides most of the melt pump, is the use of chains to achieve the motor and melt pump pump shaft connection, which is also an important difference between professional manufacturers and non-professional manufacturers; because the pump coupling, reducer, motor after installation of the coupling and its horizontal line angle is less than or equal to 3 degrees, which is also an important factor causing the melt pump in the process of use of the pump card.

Fishnet wire production using mesh belt type automatic screen changer, installed between the barrel flange and cartridge filter connection flange, the back of the cartridge type can generally be retained, can also remove the cartridge filter, behind the screen changer to make a right-angle runner flange also spinneret connection can be, generally installed after the screen changer recommended that the spinneret also retain the original screen, do not remove, the purpose is to prevent individual fine impurities through the screen changer filter The purpose is to prevent individual small impurities through the screen changer filter screen appears after the broken silk phenomenon.

The filtration precision of fishing wire production is relatively high, and the filter mesh of the mesh belt changer is a mat type contrast mesh, woven into a different way than the flat woven mesh, so the single layer mat type mesh can not meet the corresponding filtration precision process requirements, so it is recommended to use Batte double mesh belt automatic mesh changer to meet the process requirements of fishing wire production. The netting wire production screen changer is also installed between the barrel flange and the cartridge filter connection flange, basically the same as the fishing wire production installation. Double-headed extrusion installation of the net changer should pay attention to the net away from the direction of movement, generally using a left and a right to go to both sides of the net. Rope-making wire, strip broom wire, tooth razor wire and other installation of the net changer is also basically the same; woven belt drawing using no net slag filter; chemical fiber spinning wire is generally used in a large area of double column type net changer.