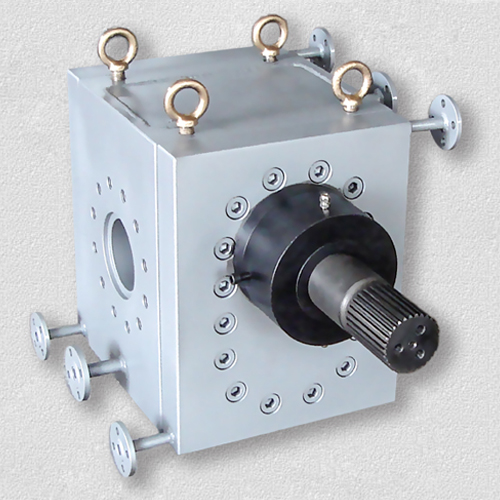

Gear pump for extrusion is mainly used in conjunction with extruders.

Extrusion gear pumps provide consistent polymer flow, which results in more consistent product dimensions. It reduces the natural pulsation and irregular conveyance, particularly in single-screw extruders, added to which, the build up of pressure in the

gear pump is more efficient in comparison to the extruder. Because of this, less energy or heat is transferred into the polymer and the product is conveyed in a gentler manner. The extruder is indispensable for the manufacture of precision films or micro granulate.

The robust construction and low wear materials make the extruder indispensable for extrusions. The versions are available for conveying plastic,rubber and fiber. The BATTE quick colour change version lends itself particularly to master batch applications with frequent changes of colour.

In order to prevent the pump's drive shaft from being driven/pushed out of the housing when there is a high pressure on the suction side (extruder conveying pressure), the drive shaft must be relieved. It protrudes from both sides of the housing and is sealed, so that atmospheric pressure predominates on both sides of the drive shaft. The shaft is thus relieved.

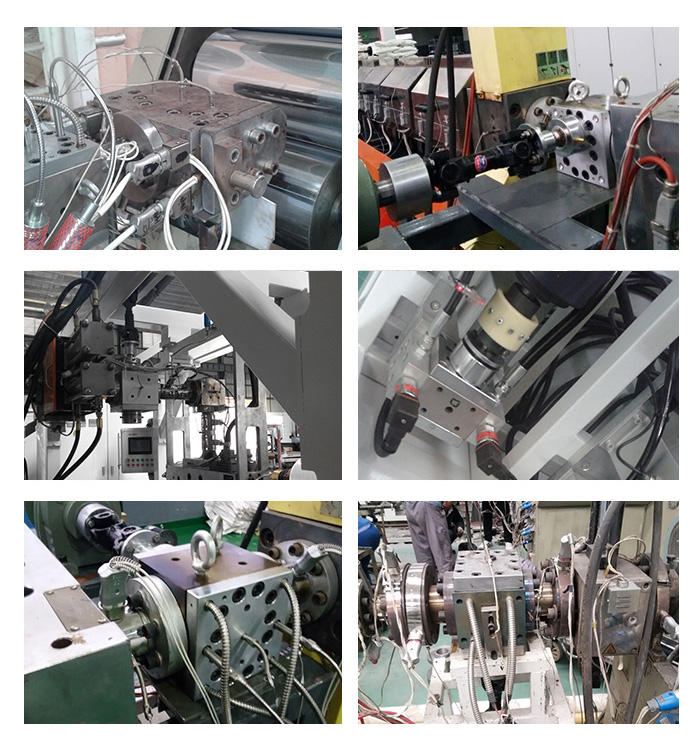

Gear pump for extrusion Applications:

Extrusion gear pumps are widely used in plastics, resins, rubber and chemical products extrusion. Such as: granulation, film, pipe, plate, sheet, synthetic fibers, fiber optics, medical plastic catheters and other industries.

Processable material covering almost the most polymeric materials, such as PE, PC, PP, PVC, HIPS, PS, PA, TPUR, fluoropolymers, polysulfones, polyesters, thermoplastic elastomer, rubber and adhesive fever.

certificate

Place of Origin: Henan, China (Mainland)

Brand Name: Batte

Model Number: ZB-B, ZB-C, ZB-D, ZB-E, ZB-F, ZB-G, ZB-H, ZB-K, ZB-R

Theory: Positive Displacement Gear Pump

Structure: Gear Pump

Usage: Plastic, Rubber Pump and Fiber

Power: Electric or Oil

Fuel: No Need

Pressure: High Pressure

Application: transportation, pressurization or the metering of polymer

Scope of Application: Almost all kinds of polymers(plastic, rubber, chemical fiber...)

Viscosity: Up to 40000Pas

Gear Tooth: Straight (Optional), Helical gear pump(Optional), Herringbone gear pump(Optional)

Sealing Method: Mechanical Sealing (Optional)

Heating Method: Stainless Steel Heating Rod

batte melt pump chinaplas

|

Packaging Details:

|

Items are packed in wooden cases.

|

|

Delivery Detail:

|

5-6 Weeks

|

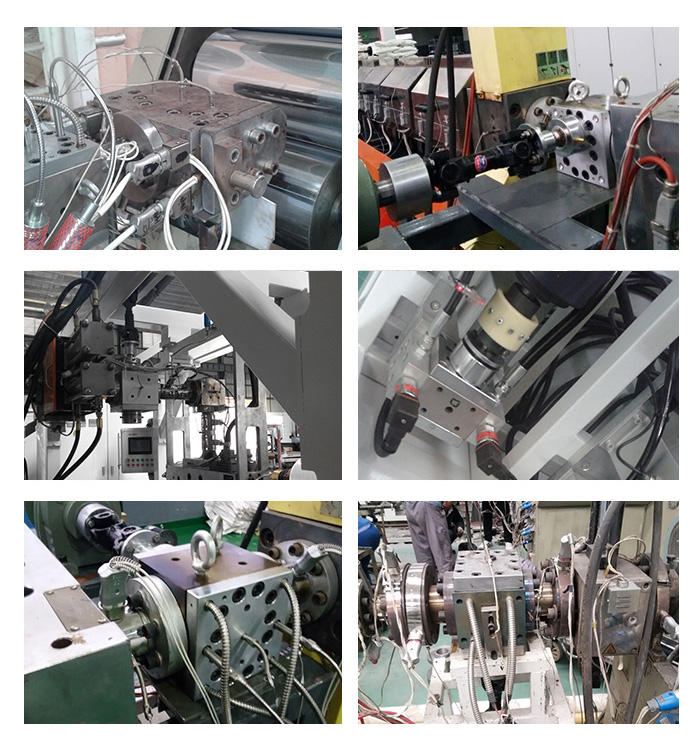

batte melt pump company

Zhengzhou Batte Melt Pump Co., Ltd. is a professional manufacturer of melt pumps, screen changers and feeders integrating R&D and production. Located in the University Science and Technology Park of Zhengzhou High-tech Industrial Development Zone, it relies on the scientific research strength of domestic universities and combines European advanced technology and quality control concepts to integrate production, learning and research. Especially in the application technology of melt pump, has accumulated rich experience. Continuous in-depth research on the working principle, performance optimization, equipment structure optimization, control technology and other aspects of the melt pump has achieved considerable results, and has been recognized and praised by the vast majority of users in the industry. info@battemachinery.com