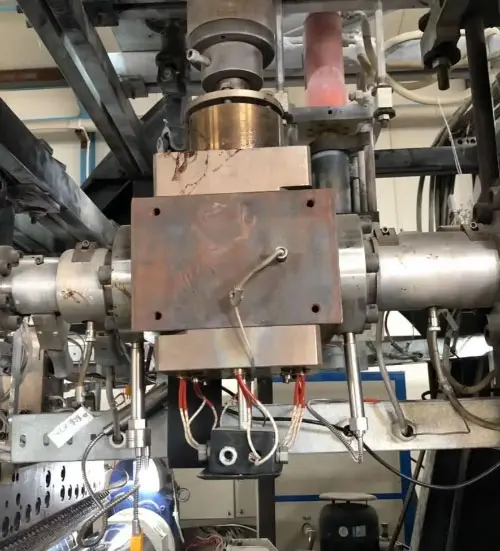

PET granulated plastic extruder melt pump is a widely used equipment in the plastic processing industry, with characteristics such as high precision, high pressure, and high efficiency. It is widely used in the production fields of PET bottle embryos, sheets, and plates.

thermoplastic melt pump manufactuer

In the working process of the PET granulated plastic extruder melt pump, the PET plastic particles need to be first added to the hopper of the extruder, and then heated and converted into a molten state through the rotation of the screw. Next, the melt is extruded through the mold mouth of the extruder, forming the desired shape and size. The melt pump of PET granulated plastic extruder plays a crucial role in this process, which can pump the melt from the inlet of the extruder to the outlet to increase pressure and flow rate, ensuring that the melt can be extruded at a stable pressure and flow rate, thereby obtaining high-quality plastic products.

The design and manufacturing of thermoplastic melt pump manufactuer need to consider the characteristics of PET materials and the working requirements under extreme conditions such as high temperature and high pressure. Therefore, when choosing a melt pump, it is necessary to choose materials with good high-temperature resistance, corrosion resistance, high strength, and other properties to manufacture the pump body and seals. In addition, it is necessary to monitor and control the inlet and outlet pressure, temperature and other parameters of the melt pump to ensure the production efficiency and product quality of PET particles.

In summary, the PET granules melt pump is an efficient and stable PET particle production equipment, mainly composed of three parts: the extruder, melt pump, and granulation machine. During the production process, it is necessary to adjust and monitor the various parameters of the equipment reasonably to ensure the production efficiency and product quality of PET particles. At the same time, regular maintenance and upkeep of the equipment is also necessary to ensure its normal operation and lifespan.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

pre:The Best Solution to Extend the Life of High Temperature Melt Pump

next: Melt pump use, internal structure and material requirements