In the actual transportation process of high-temperature melt pumps, due to the existence of unbalanced radial forces, the bearings of the high-temperature melt pump are reported to be damaged too early, resulting in early scrapping of the pump. This is an important factor that restricts the extension of the service life of the high-temperature thermoplastic melt pump manufactuer. How to effectively improve the bearing capacity, Zhengzhou BATTE melt pump manufacturer has provided the following suggestions for solutions.

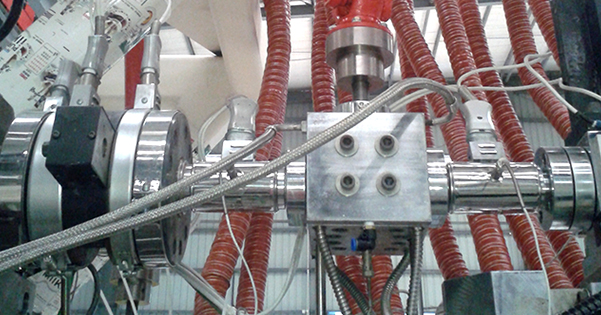

thermoplastic melt pump manufactuer

By improving the lubrication and cooling conditions of the melt gear pump bearings: Currently, high-performance and high-pressure melt pumps adopt oil suction lubrication, which utilizes the phenomenon of trapped oil in the closed volume. When the closed volume increases from small to large, a vacuum is generated, and the oil in the oil inlet chamber first flows from behind the bearing race into the bearing, and then into the closed volume. When the gear disengages, the oil in the closed volume merges with the oil in the oil inlet chamber, Bring it into the oil discharge chamber. As the oil temperature at the inlet is lower than that at the outlet, using oil suction lubrication can reduce the bearing temperature and enable the bearing to withstand greater loads.

melt gear pump

By improving the performance of bearing materials and improving the bearing structure: due to the bending of high-temperature melt pumps under radial force, concentrated loads are generated on the journal and bearings near the gear end face. Therefore, for melt gear pumps that use rolling bearings, if the journal is ground to a reverse taper with a small inner diameter and a large outer diameter, the service life of the bearings can be improved, thereby enhancing the service life of high-temperature melt pumps

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

pre:How much output can the extruder and melt pump increase?