Blowing film technology is a common and important technique in the production process of plastic films. With the continuous development and progress of technology, the requirements for blown film technology are also increasing, especially in the application of high-temperature melt pumps. This article will introduce the characteristics, applications, and future development of high-temperature melt pumps for film blowing, and explore their key role in achieving high efficiency and precision film blowing.

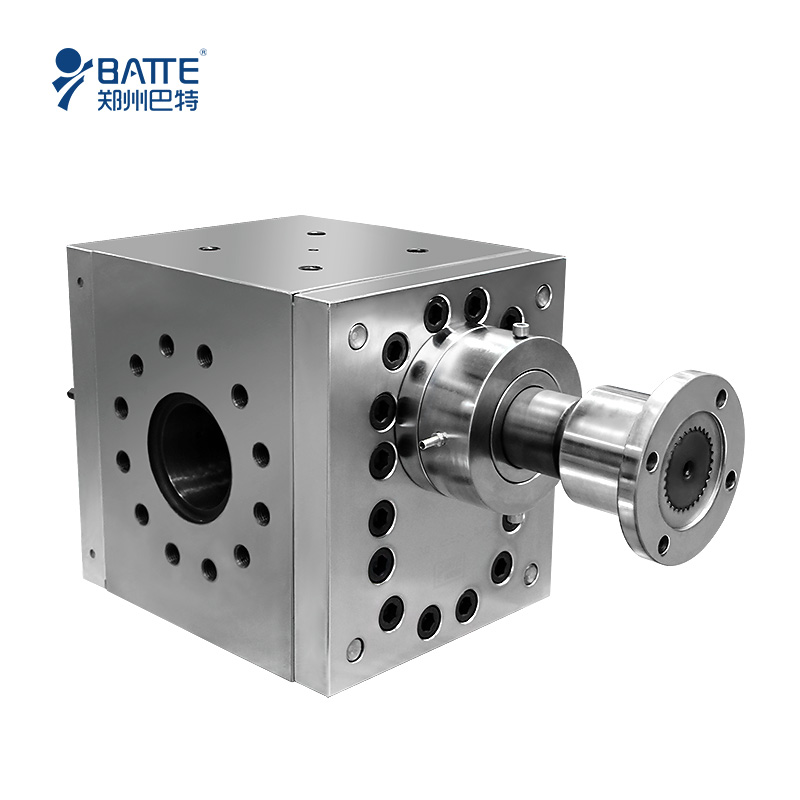

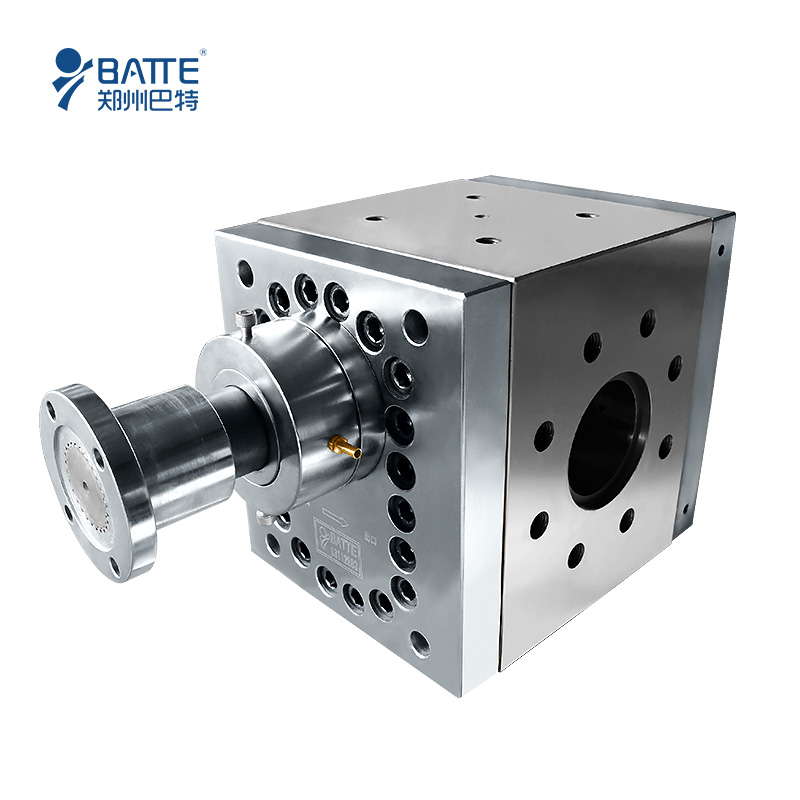

Blowing film high-temperature melt pump is a specialized equipment used for plastic film production, which mainly features:

1. High temperature stability performance: The blown film high-temperature melt pump can operate stably in high-temperature environments, ensuring the stability and uniformity of melt temperature, and improving the quality and stability of plastic films.

2. High flow output: The blown film high-temperature melt pump has the characteristic of high flow output, which can meet the needs of large-scale production and improve production efficiency.

3. Accurate pressure control: The blown film high-temperature melt pump can achieve precise pressure control, ensuring uniform output of the melt and effectively avoiding quality problems during the production process.

4. Long service life design: The blown film high-temperature melt pump adopts high-quality materials and advanced design concepts, which have a long service life and lower maintenance costs.

Blowing film high-temperature melt pump has a wide range of applications in plastic film production, mainly manifested in the following aspects:

1. Polyethylene film: Polyethylene film is a common plastic film widely used in packaging, agriculture, construction and other fields. The blown film high-temperature melt pump can ensure the stable output of polyethylene melt, improve the transparency and strength of the film.

2. Polypropylene film: Polypropylene film has good heat resistance and insulation properties, and is widely used in fields such as electronics, appliances, and automobiles. The blown film high-temperature melt pump can ensure the uniform output of polypropylene melt, improve the flatness and thickness control accuracy of the film.

3. Polyvinyl chloride film: Polyvinyl chloride film has good corrosion resistance and barrier properties, and is widely used in chemical, environmental protection, medical and other fields. The blown film high-temperature melt pump can ensure the stable output of PVC melt, improve the toughness and durability of the film.

With the continuous strengthening of environmental awareness and the increasing energy consumption, the plastic film industry is facing increasing pressure and challenges. In order to meet market demand and improve competitiveness, the blown film high-temperature melt pump needs to develop towards a more efficient, intelligent, and environmentally friendly direction. Specifically, the future development focus includes the following aspects:

1. Efficient and energy-saving technology: By optimizing design and adopting efficient and energy-saving technology, the energy consumption and energy waste of the blown film high-temperature melt pump are reduced, improving production efficiency and reducing production costs.

2. Intelligent control technology: Introducing intelligent control technology to achieve remote monitoring and automatic control of blown film high-temperature melt pumps, improving equipment automation and production efficiency. Meanwhile, intelligent control technology can also improve the fault diagnosis and early warning capabilities of equipment, reduce maintenance costs and downtime.

3. Environmentally friendly materials and processes: Adopting environmentally friendly materials and processes to reduce the impact of blown film high-temperature melt pumps on the environment. For example, using renewable energy and environmentally friendly materials to make accessories such as melt pipes and valves can reduce the amount of waste generated and carbon emissions from equipment.

4. Expand application areas: On the basis of maintaining traditional application areas, further expand the application areas of blown film high-temperature melt pumps. For example, it has broad application prospects in fields such as biomedicine, electronic devices, optical instruments, etc. Through continuous exploration and innovation, its application in more fields can be achieved.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071