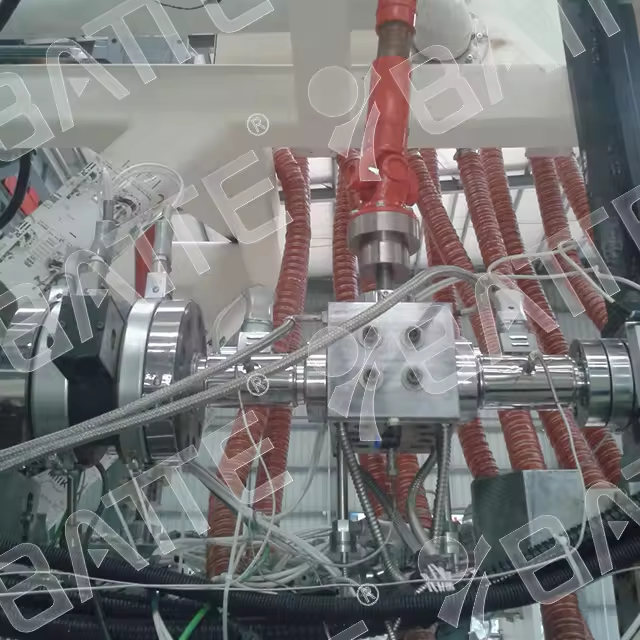

Gear pump is one of the important equipment in the blow molding film extrusion production line. Its function is to transport the molten plastic to the blow molding mold through the rotation and extrusion of gears. Due to the continuous, efficient, and stable production requirements of blow molded film extrusion production lines, the performance and stability of gear pumps are crucial for the normal operation of the production line.

The blow molded film extrusion melt gear pump is a special type of gear pump, which works similarly to conventional gear pumps, both of which achieve the transportation of plastic melt through the rotation and extrusion of gears. However, blow molded film extrusion melt gear pumps have higher requirements in design, materials, manufacturing processes, and other aspects to meet the special needs of blow molded film extrusion production lines.

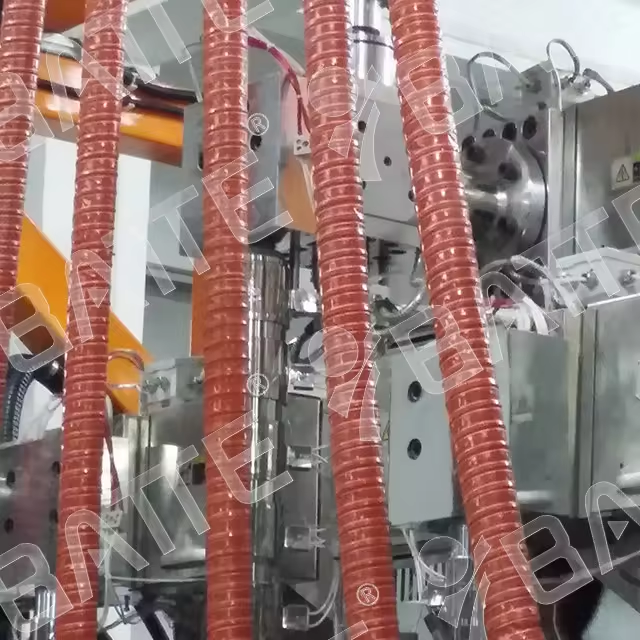

Firstly, the gears of the blow molded film extrusion melt gear pump must be made of high-precision and high hardness materials to ensure their wear resistance and corrosion resistance. At the same time, the design of gears must be very precise to ensure their stability and accuracy in rotation and compression.

Secondly, the sealing performance of the blow molded film extrusion melt gear pump is extremely high, and it must be able to prevent the leakage and pollution of plastic melt. Therefore, sealing materials and designs must have excellent high-temperature resistance, corrosion resistance, and wear resistance.

In addition, the driving and control system of the blown film extrusion melt gear pump is also one of the key factors in its performance. The driving system must be able to provide stable and efficient rotational power, while the control system needs to accurately control parameters such as pressure and flow to ensure stable quality and uniform thickness of the blown film produced.

Overall, the blown film extrusion melt gear pump is a highly specialized equipment, and every step of its design, manufacturing, and use must go through strict control and management. Only by ensuring the performance and stability of the gear pump can the continuous, efficient, and stable production of the blown film extrusion production line be guaranteed.

In practical applications, blow molded film extrusion melt gear pumps also face some challenges and problems. For example, due to the characteristics of plastic melt and changes in production conditions, the performance of gear pumps may be affected. To solve these problems, a series of measures need to be taken, such as optimizing design, selecting more suitable materials, improving manufacturing process level, strengthening equipment maintenance and upkeep, etc.

Meanwhile, with the continuous development of technology, blow molded film extrusion melt gear pumps are also constantly being upgraded and improved. In the future, with the application of new materials, processes, and technologies, the performance and stability of blow molded film extrusion melt gear pumps will be further improved, providing a more reliable guarantee for the development of the blow molded film industry.

In summary, the blown film extrusion melt gear pump is one of the important equipment in the blown film extrusion production line, and its performance and stability are crucial for the normal operation of the production line. In order to ensure continuous, efficient, and stable production, it is necessary to adopt highly specialized design and manufacturing technologies, strengthen equipment maintenance and upkeep, and continuously upgrade and improve equipment performance. With the application of new materials, processes, and technologies, the development prospects of blown film extrusion melt gear pumps will be even broader.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

pre:What factors need to be considered in the selection of melt pumps?