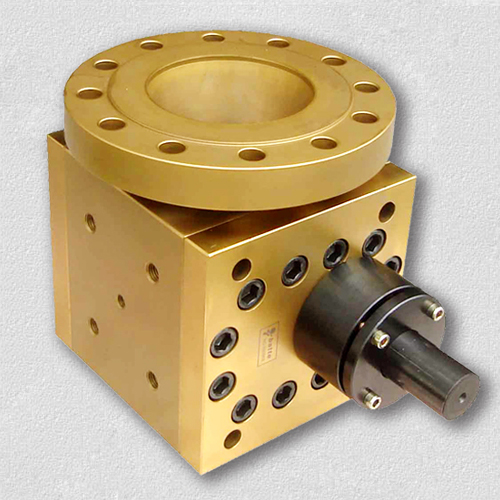

All gears and mating surfaces are grinded and assembly clearance is strictly controlled to obtain accurate flow rate.

The gear and the pump body according to the different conditions of ZB-B series using chromium nickel alloy steel, high temperature steel materials; ZB-H series adopts imported CPM tool steel or titanium tantalum alloy materials, quenching, HRC62-68 hardness, good abrasion resistance.

1. ZB-B series: working temperature: <400 (), cleaning temperature: <450 (), outlet pressure () 40 MPa (6,000 psi) viscosity: <4000Pa.s (4,000,000 cp)

2. ZB-H series: working temperature: 510 (950) cleaning temperature: <590 (1100), outlet pressure <70 MPa (10,000 psi) maximum differential pressure: 50 MPa (7,000 psi) viscosity: <2000 Pa.s (2,000,000 cp)

3. Sealing: Spiral and packing seals are generally used, and other mechanical seals can also be used according to customer requirements.

4. Driving: motor + reducer + universal coupling + pump body, motor adopts frequency conversion speed regulation, can be adjusted to the required flow at will, also can be used in the form of DC speed regulation and servo drive according to customer requirements.

5. Heating: The melt pump can accurately control the melt temperature by using electric rod heating or heat medium heating.

pre:What are the gear heat treatment methods of melt gear pump