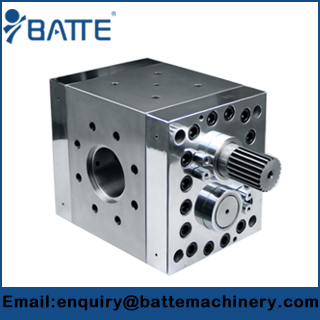

BATTE Circular Melt Pump

BATTE circular melt pump have a unique positive displacement design which provides consistent, accurate plastic delivery under varying extruder output conditions of pressure,temperature and viscosity.

BATTE Circular Melt Pump Advantages:

1. stable output pressure, can effectively reduce the extrusion parameters caused by the unstable output of material and pressure pulsation.

2. improve the quality of the product dimensions and tolerances -- will minimize the extrusion products, reduce waste and scrap rate. Common extrusion machine can produce high

precision products.

3. increase the output, reduce the pressure of the screw, the screw to die pressing, to gear pumps to the die head pressure, the screw can be high speed extrusion.

4.can adjust the pressure to reduce the extruder, meltresidence time in screw cylinder, stable plasticizing process, reduce the melting temperature, improve the yield and quality of

products.

5. reduce unit energy consumption, data showed that the same granulation to twin screw extruder and melt pump combination, the mixing quality and yield is greatly improved.

6.the twin-screw granulator unit separate. Energy consumption per kilogram of materials processing can be reduced by about 1/4.

BATTE Circular Melt Pump Application:

ZB - E series melt pump is mainly used for round body of high viscosity polymer extruder or pressurization and steady flow.Mainly for electrical heating heating way.

Applies to PS.PET. PVC. PC. PA. PMMA. HDPE. LDPE, LLDPE, PP, and so on in the process.

Relative Articles:

◆Pipeline Pump Extrusion

◆Extrusion Moulding Pump

◆Gear Metering Pump For Viscous Products

◆Precision Gear Metering Pumps

pre:Batte Gear Melt Pumps Price And Quality

next: Hot Melt Glue Pumps