Melt pumps are usually used in plastic processing together with single or twin screw extruders. They can further homogenize the melt, stabilize the pressure, and ensure no pulsation in material output, thereby improving the quality of the product. This equipment is not only used for plastic melt granulation and mixing, but also for extruding sheets, pipes, films, and profiles.

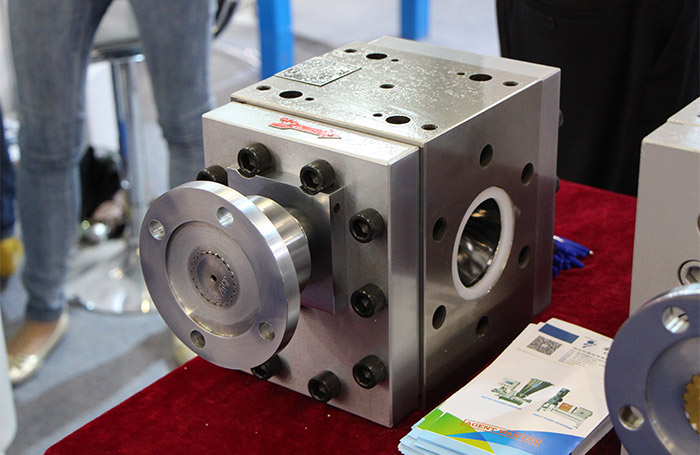

plastic extrusion melt gear pump

The working principle and main structure of the melt pump are similar to those of gear pumps in hydraulic systems. However, due to the unique nature of plastic processing technology, its material selection and structural design have unique characteristics. In plastic processing, the melt pump is installed between the extruder and the head. In this way, the fluctuations generated in the extrusion direction can be isolated from the machine head and downstream equipment. Regardless of whether the pressure at the pump inlet fluctuates, as long as the melt entering the pump can fully fill the teeth, it can transport materials to the machine head at a stable pressure and flow rate, and ensure that the machine head does not experience fluctuations in extrusion, thereby improving the stability of the system and product accuracy.

melt pump in plastic processing

At the same time, due to the fact that the melt pump is a pressure boosting device, it can transfer the pressure stabilizing and boosting function of the extruder metering section to the melt pump to complete, thus avoiding the shortcomings of high power consumption, high shear force, severe friction, long material retention time, and easy degradation that exist when the extruder operates under high head pressure, resulting in increased extrusion productivity and reduced wear and tear of the extruder.

In addition, the use of melt pump can also increase the Controllability of the system, reduce the melt temperature, reduce energy consumption, and achieve linear output. In the entire extrusion system, various process parameters are controlled by a microcomputer, which can elevate the plastic extrusion molding technology to a new level.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071

pre: Application, Parameters and Installation Mode of reactor melt discharge pump