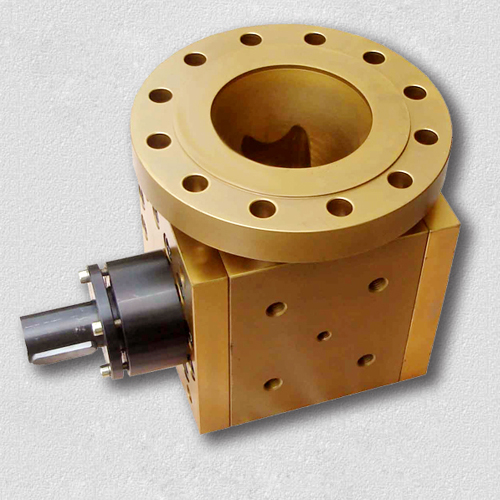

Chemical melt gear pump

Chemical melt gear pump housing, front and rear side cover, gear shaft, sliding bearings and shaft seal form. Chemical melt gear pump is a positive displacement pump, work rely on the main and driven gears caused by the intermeshing changes in the volume of work to transport the melt. Working volume by the pump body, gear tooth groove and the function of the side plate with the composition. When the gear rotates, the melt enters the tooth grooves of the two gears of the suction chamber. As the gear rotates, the melt is brought into the discharge cavity from both sides, and the gears mesh again to make the melt in the tooth grooves to be squeezed out Cavity, pressure delivery to the outlet pipe. As soon as the pump shaft is turned, the gear presses the melt down to the outlet side so that the pump outlet can reach very high pressure with little or no effect on flow and discharge pressure.

Common high-viscosity chemical gear spur, helical, herringbone, helical teeth, tooth profile are mainly involute and arc type. Usually use more small gear pump involute spur gear, high temperature chemical often use variable gear, conveying high viscosity, high pressure melt polymer melt more use of involute helical gears. Gear and shaft made of one, its rigidity and reliability is higher than gear and shaft separately manufactured gear pump. Foreign low-pressure melt gear pump gear is often used square structure, that gear tooth width equal to the addendum circle diameter. The high-pressure occasions used in high-viscosity chemical melt gear pump gear tooth width less than its tip diameter, which is to reduce the gear radial compression area, reduce gear, bearing load.