1. Carefully open the melt pump package carefully and check for any damage or missing parts. Contact your company immediately. The pump is made of high-temperature alloy steel, all parts are heat treated to a higher hardness, so the material is more brittle precision equipment. Any impact and impact may cause serious damage, it is recommended to install rings.

2 installation, please accurately determine the melt pump inlet and outlet. The melt pump shaft is clockwise when installed correctly. Install the motor, reducer, universal coupling and melt pump, the pump must be installed on the base fixed to ensure that the melt pump seat and motor drive shaft concentricity, rotation must be no lag, otherwise it will cause the gear housing, Serious shaft rupture.

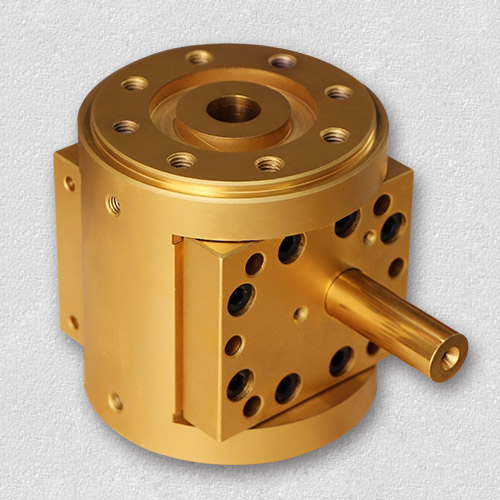

3. Melt pump pump body The appearance of the pump are left pressure sensor hole and temperature sensor hole, due to the correct installation of the sensor, or measurement data deviation. High strength (12.9) bolted connections at the pump body ensure safe operation of the melt pump body.

Just start the melt pump should be low speed operation. After the melt pump runs steadily, it can be gradually adjusted to the normal speed and pressure. If the pump does not rotate smoothly, you must stop the pump to check the cause to avoid serious damage to the inside of the pump. If the use of packing seal, often adjust the position of the seal cover, the seal is always in the best condition.

next: Application of metering gear pump in extrusion production line